|

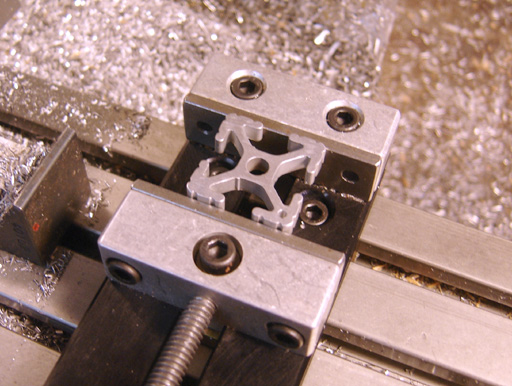

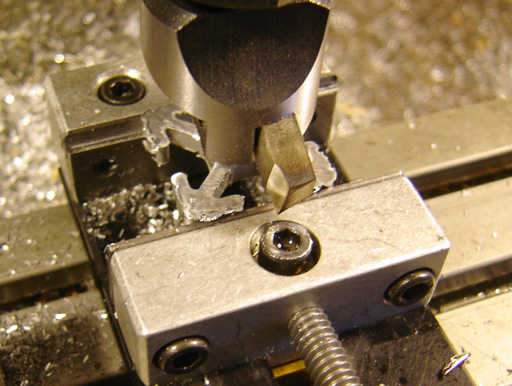

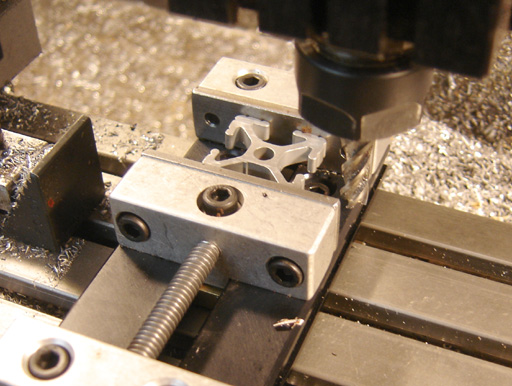

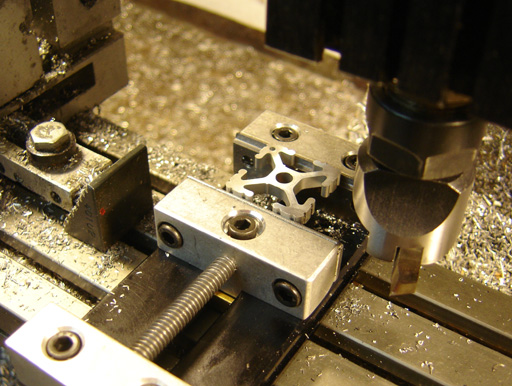

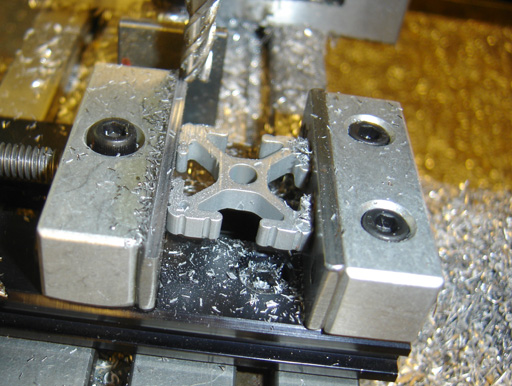

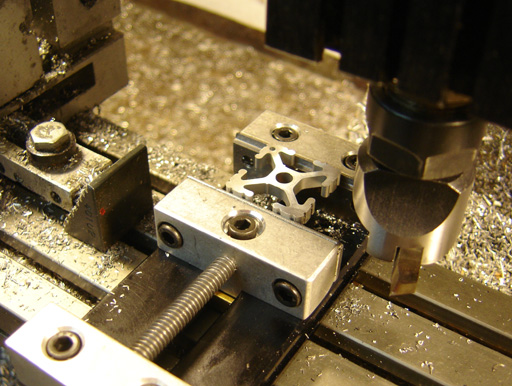

I needed to face both sides of these extrusion slices. |

|

Using one of the slices to load the jaws I found the edges

and cut a .075" wide by .05 deep step. |

|

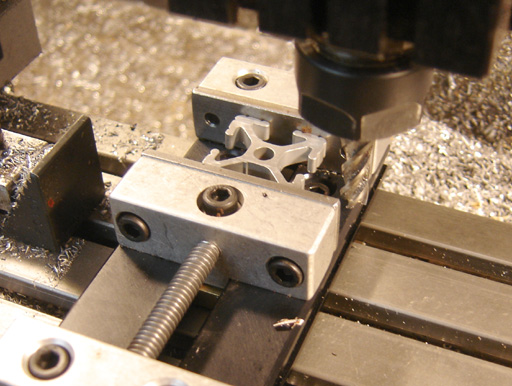

The jaws are mild steel and cut easily. |

|

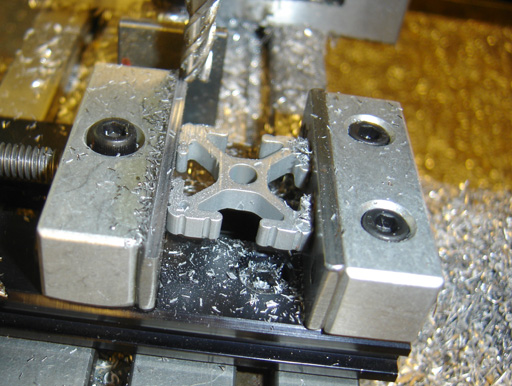

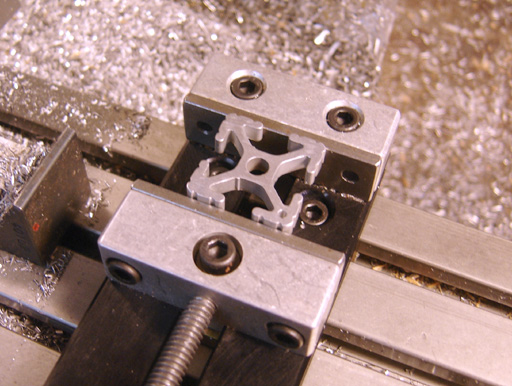

The other side. |

|

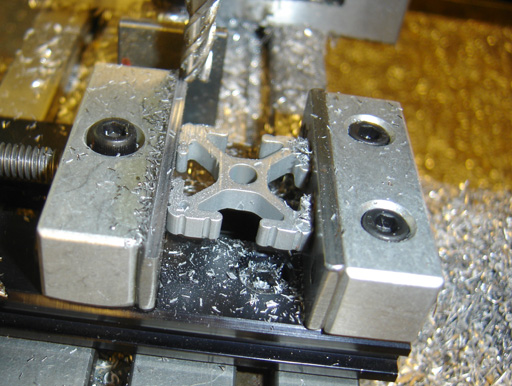

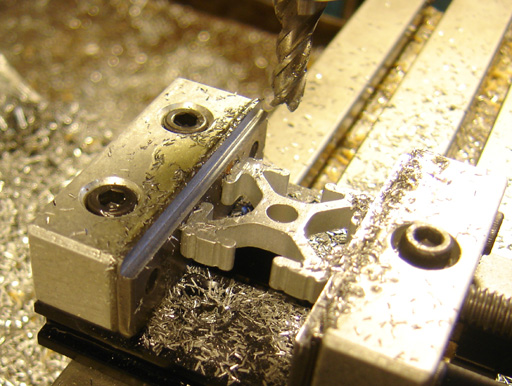

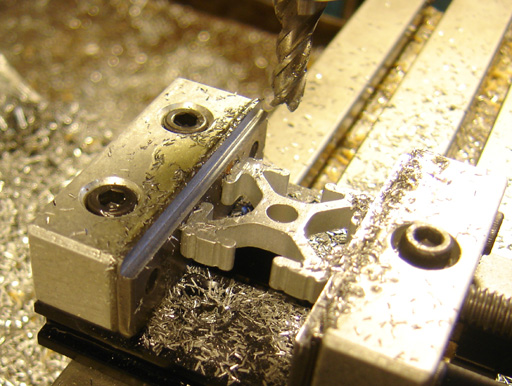

After running the cutter into the screw on the moveable jaw

I decided to recess it further... |

|

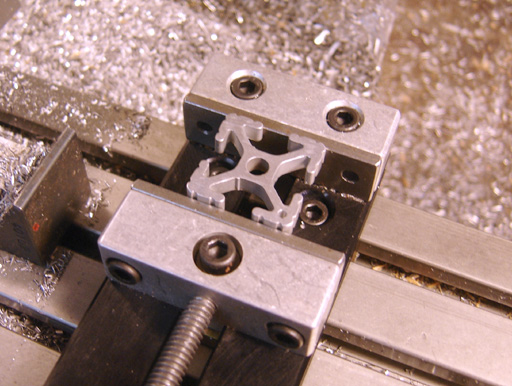

Taken apart. |

|

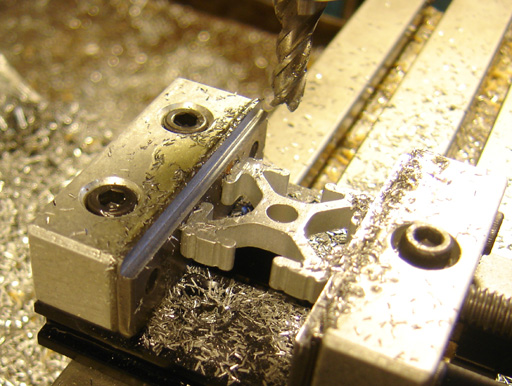

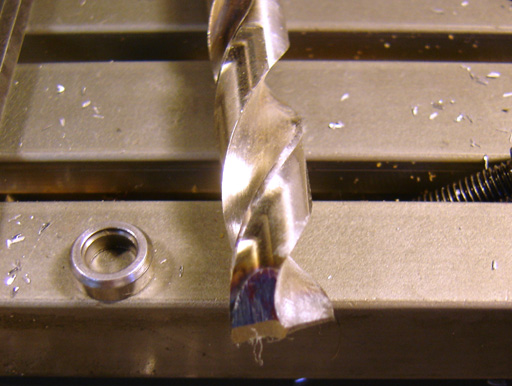

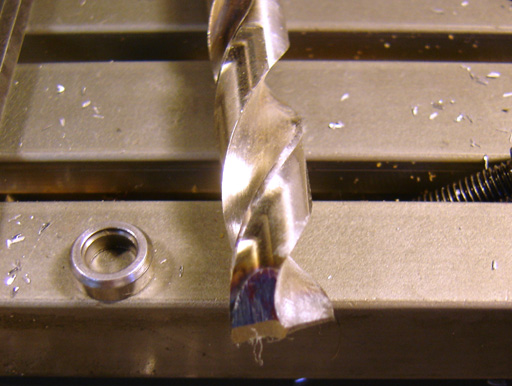

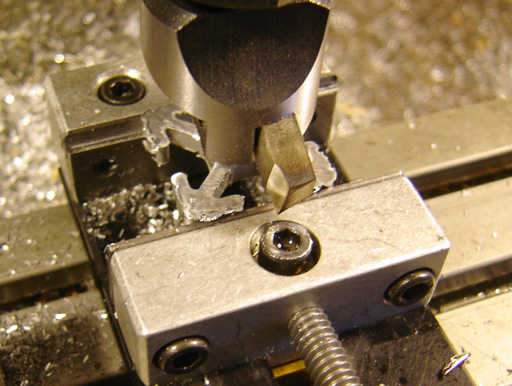

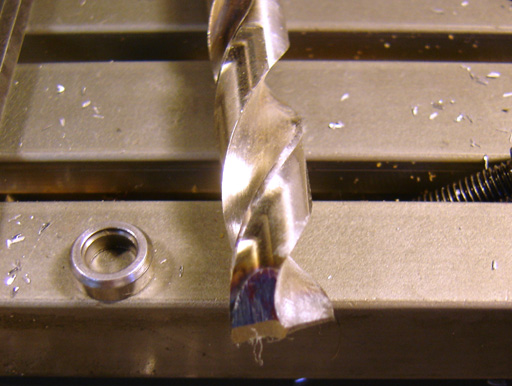

I ground a flat bottom drill. |

|

Drilled with a regular drill to depth. |

|

Then used the flat bottom drill to counterbore. |

|

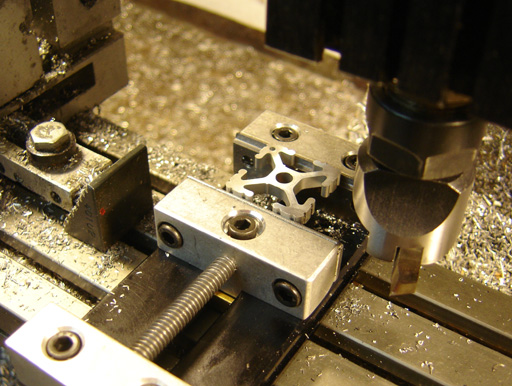

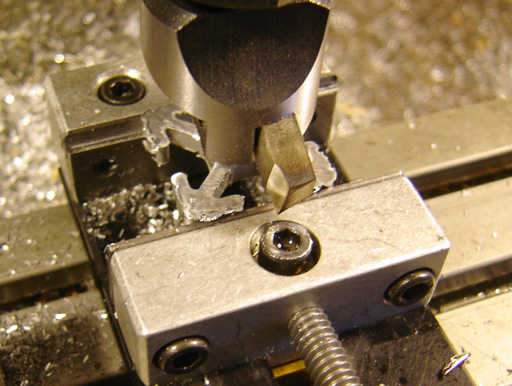

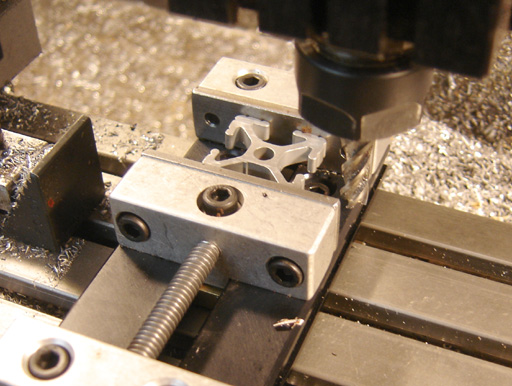

Now it's easy to face the slices. You could even make soft

jaws for the Taig vise easily. |

|

What are the slices for? Well

earrings of course. |