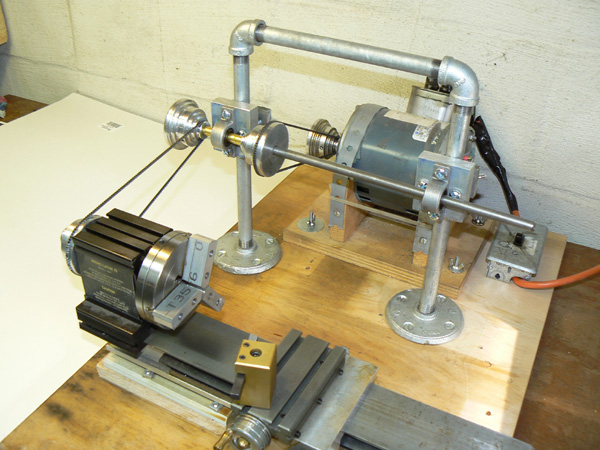

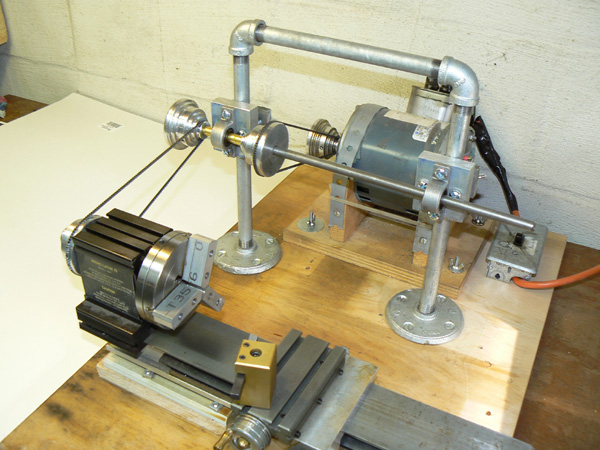

| In an attempt to slow down the spindle speed of my Taig, in particular

so I could try to turn cast iron locomotive driver castings for my gauge

0 and gauge 1 live steam locomotives, I decided to construct a jackshaft

(intermediate shaft) utilizing as many off-the-shelf components as I could

find. I purchased some 5/8" galvanized pipe fittings at the local home center

-- three straight lengths, two 90 degree elbows, and two floor flanges.

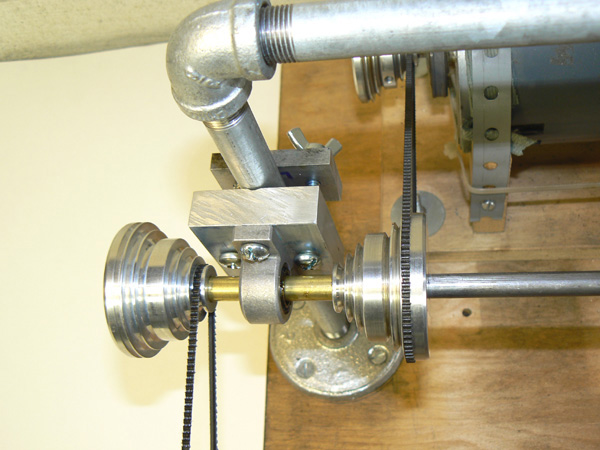

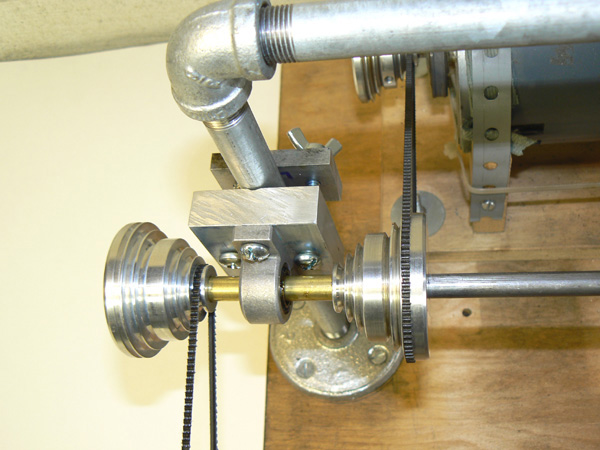

The shaft itself was made from 3/8" steel bar. I purchased two pillow blocks

from MSC:

#07571144 Spiraflow Self-Aligning Needle Roller Mounted Bearings, i.d.

0.375". I also purchased another pair of Taig pulleys and an additional

Gates belt from Nick Carter.

|